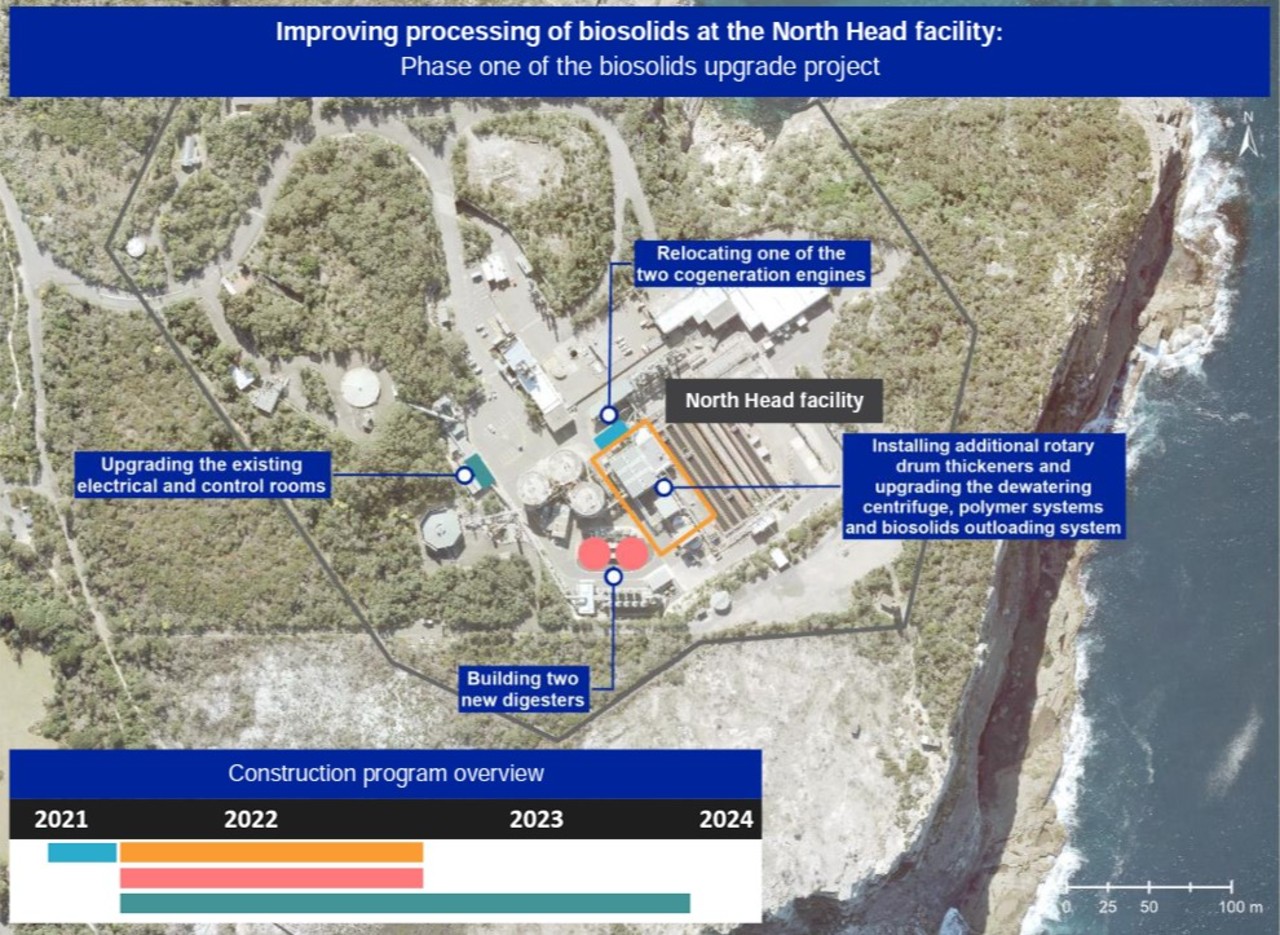

In 2019, we refined concept designs and started detailed planning to determine project scope, timing and budgets. Detailed plans identified that the project budget exceeded anticipated funding and we decided to split the project into 2 parts, primarily for funding purposes and to manage the scope, timing and deliverables better.

Delivering this project in 2 phases helps us better plan with and around other projects and upgrades at the North Head facility, safely coordinate crew movement, and minimise cumulative impacts to the local Manly community.